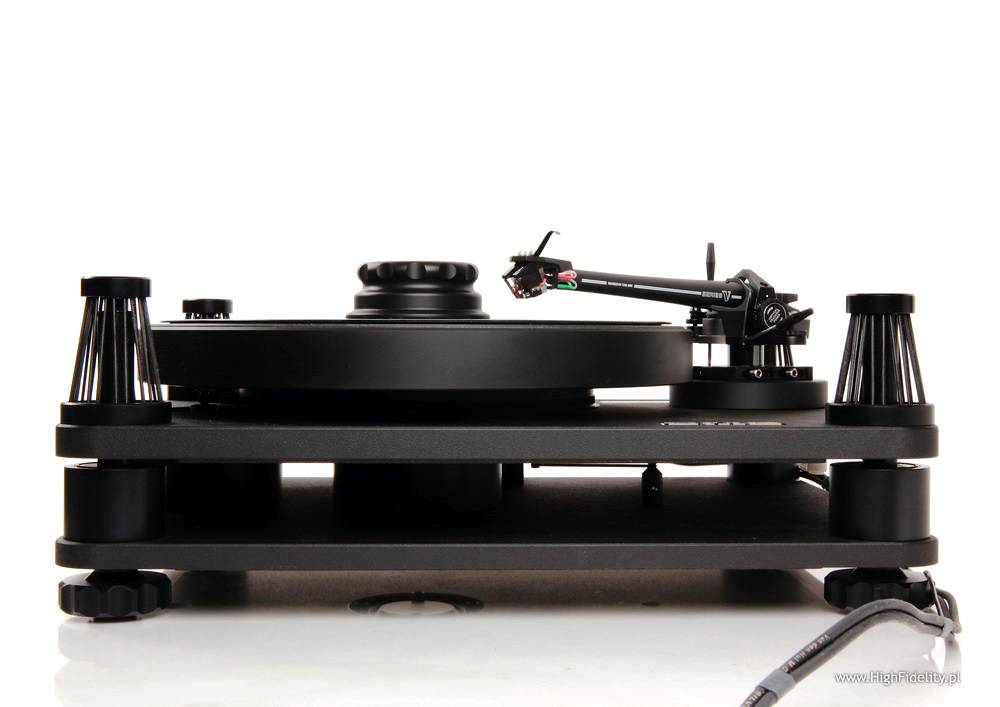

SME30/2 with SME V Tonearm, Kimber KS1216 cable, Koetsu Rosewood

Original price was: R650,000.00.R188,000.00Current price is: R188,000.00.

Turntable

Width: 450mm

Depth: 350mm

Height (top of tonearm): 220mm

Speed Control Unit

Width: 150mm

Depth: 295mm

Height: 82mm

Power Unit

Height: 82mm

Width: 188mm

Depth: 242mm

Platter: 330mm

Weight

Turntable: 42kg

Power Unit: 4.04kg

Speed Control Unit: 2.52kg

Shipping Weight: 56kg

The MK2 Model 30 is a precision turntable made to exacting engineering standards for extreme performance. The chassis and sub-chassis are CNC machined from premium grade aluminium billet and acoustically treated. The sub-chassis is stiffened with a lateral brace for improved chassis flex and vibration control. The suspended suspension system provides definitive resonance control and houses the main bearing, platter and tonearm. In addition, the sub-chassis motion is finely disciplined by fluid dampers within the four suspension columns. All four feet are fully adjustable and mechanically de-coupled from the main chassis by way of isolators.

The main spindle is 19mm in diameter, precision machined from high chrome tool steel, ground, super finished and supported in a sealed housing with individually fitted sintered bronze bearings of generous proportions needed for precise bearing and platter rotational control.

Description

SME Model 30/2 turntable

Dense, compact, and built to run O-rings around the competition, SME’s flagship turntable makes every other design I’ve encountered—with the possible exception of Rockport’s System III Sirius—look almost homemade. I don’t mean to insult the many fine, well-engineered designs out there, but I’ve seen nothing else to compare with SME’s tank-like approach to spinning a record. Comparing the Model 30/2 to a tank isn’t exactly fair: the machining is done to higher than mil-spec tolerances. I don’t think anyone else building turntables today is capable of this level of construction quality, never mind design ingenuity and fit’n’finish.

So many fanciful pieces of acrylic eye-candy are designed to appeal first to the visual sense, and so many have design “features” that simply don’t make technical sense. But this impressively hunk of black metal is not the turntable to impress your friends with—until you play a record on it. The no-nonsense SME 30/2 is, as Rockport’s Andy Payor describes a turntable’s true role, a genuine “reverse machine tool.”

From Crate to Playback in Minutes

Weighing 94 lbs, the SME 30/2 comes packed in an industrial strength wooden crate designed for rough handling and easy opening. Unless you’ve been pumping iron, lifting this turntable out of its box is a two-man operation. Place it on a sturdy stand and you’re 15 minutes or so from your first spin (not counting arm and cartridge setup).

First, you inject (with the supplied syringe) a pre-measured charge of oil into a pre-fitted adapter located at the base of the bearing. You then unscrew and save the adapter. Then, all that’s left to do is unlock the four suspension towers using the supplied ball-ended wrench, unscrew the motor transit screw using the supplied tool, adjust the motor-height screws using another supplied tool and height adjustment gauge, unlock the main bearing, fit the drive belt and platter, and, finally, level the base via the four threaded feet (a spirit level is built in). At this point you’re ready to install an SME tonearm, using the supplied mounting plinth of solid brass, or a plinth appropriately drilled for your choice of arm.

All of these preparatory maneuvers reinforce the precision engineering and design acumen that went into the 30/2’s construction. The machining quality of the proprietary setup tools and the smoothness and unfailing certainty with which the various locking screws rotate in their threaded sockets—not to mention the feel of the unlocking mechanisms—enhanced my confidence that the buyer’s money will be well-spent. The 30/2 is an heirloom product meant to be enjoyed and passed down from generation to generation.

Once the arm plinth has been secured with the four supplied socket-cap screws, all that’s left to do is adjust the height of the suspended subchassis, fit the motor-controller cord to the chassis-mounted DIN jack, and plug the unit into the AC. There’s no fiddling with setup, and the few adjustments that need to be made have a certainty about them that won’t leave you feeling the need to tweak.

Design Rationale

High mass, compactness, and stiffness combine to reduce flexing and vibrating—two things you don’t want a plinth to do. The SME 30/2’s base of 5/8″-thick aluminum alloy (plus support pillars) and its ¾”-thick suspended subchassis weigh 38 and 35 lbs, respectively, with approximate dimensions of 17.75″ wide by 13.75″ deep—truly, a compact disc player! An additional bar of aluminum alloy runs the length of the subchassis at about a third of its width for additional stiffness and mass. A damping layer appears to have been added to all surfaces, further reducing the amplitude and Q of whatever vibrational modes remain. Tapping on any of the surfaces yielded a short, lifeless, colorless thup.

Designing a suspended subchassis that will operate at the effectively low resonant frequency of 3Hz that’s necessary for true isolation is fraught with difficulties. SOTA and Rockport tried this, and both companies’ results were equally problematic. On some SOTA models, the spring-hung subchassis oscillated like a porch glider when the arm’s mass would shift back and forth due to record eccentricities. Ditto the air-suspended Rockport Capella, which I reviewed years ago for The Abso!ute Sound. The motors of both ‘tables were hard-mounted to their bases; when the subchassis was horizontally deflected, the platter-to-motor pulley distance would vary, causing speed irregularities. On the Rockport, the problem was exacerbated due to the linear-tracking tonearm’s relatively high horizontal mass. Fitting the SOTA with an Eminent Technology arm (a popular combo in the early 1990s), with its moving rail and thus even higher horizontal mass, created an even bigger deflection—but even a pivoted arm caused movement.

SME’s solution to the “porch glider” effect was to hang the subchassis on 48 specially made O-rings (12 per tower), for a total of 96 strands, in combination with damping systems of a paddle in thick fluid: one damping system per tower. Should you need to replace the O-rings (not likely, unless buying the ‘table causes a divorce and your soon-to-be-ex takes a box-cutter to them), it can be done almost instantaneously—even while a record is playing, according to SME. The damping system all but eliminates horizontal deflection, while the adjustability of the degree of damping lets the user adjust the system to various conditions of acoustical and floor-borne feedback.

And, of course, the four towers are easily locked down to prevent fluid spillage during transportation. A.J. Conti’s Basis Debut uses a cartridge-based fluid-damping system that’s quite effective in its own right, while Harry Weisfeld’s TNT and HRX ‘tables use air bladders, which must be carefully under-inflated to keep their resonant frequencies low enough to be effective. However, other than the air-suspension system used in Rockport’s System III Sirius, SME’s is the most effective isolating system I’ve seen.

The oversized (13″, 17.6 lbs) platter rotates on a 6.75″-long, ¾”-diameter spindle bearing made of high-carbon, chrome-tooled steel machined to a 1;um tolerance (better than mil-spec) and enclosed in a sealed oil bath. The bearing runs on individually fitted sintered bronze bearings enclosed in a massive sealed housing rigidly fitted to the suspended subchassis.

The three-phase, eight-pole motor is electronically commutated, free of “cogging effect,” and weighs 5 lbs. It’s isolated on adjustable urethane mounts, and drives the platter via a crowned stainless-steel pulley machined to ±2.5;um. The pulley is secured to a ground tungsten-steel shaft with twin grub screws to maintain concentricity and rotational balance. When you see a pulley mounted with a single set-screw, think about it: for the shaft to fit into it, the diameter of the pulley’s mounting hole needs to be wider than the diameter of the shaft. If you secure the pulley with a single set-screw, it must be offset from the shaft’s center—no matter how well it’s machined, it’s not going to be concentric.

The motor drives an 8.25″, 5-lb subplatter via a ground-rubber belt. Three selectable, trimmable speeds—33 1/3, 45, and 78rpm—are available from the outboard power supply. Once a speed has been chosen, the platter reaches speed quietly, smoothly, and quickly. A greater variation in speed is available for 78s, for which there were so many nonstandard speeds.

Other points worth mentioning: As with the far less expensive SME Model 10, which I reviewed in the April 2000 Stereophile, the platter face is made of softer-than-vinyl Isodamp, diamond-turned with a fine scroll that imparts a fiber-like finish said to improve record-platter intimacy. There’s a heavy, screw-on, machined reflex clamp. The heavy brass arm-mounting plate fits on tiny alignment pins and is machined to such tight tolerances that two small “jacking screws” are threaded through the plate—you have to screw them down to lift the plate, and even then, it’s not easy. This is indicative of the 30/2’s machining quality and fit’n’finish, and it’s what you should expect in any ‘table costing more than $10,000. Should you use a variety of tonearms, your setup will be precisely maintained.

There you have it: a no-BS, industrial-grade turntable using one high-quality motor plus electronic drive, a crowned stainless-steel pulley, a compact, high-mass plinth system, ultra-low-tolerance machining everywhere, zero use of acrylic, and a truly effective isolation system.

I went into the listening part of the review figuring I’d like the sound of the 30/2. As much as the Rockport System III Sirius that I reviewed in August 2000? I sure hoped so, considering the differences in price, size, and complexity. If the 30/2 was almost as good as the Rockport—let alone better—that would be good news indeed.

Hello, Darkness, My Old Friend

Jim Alexander, Sumiko’s analog specialist, stopped by to set up the Model 30/2, though it was so simple that even a hi-fi dealer could do it. The supplied SME IV.Vi tonearm ($3000 without cable) was fitted with a Sumiko Celebration cartridge, so that’s what I listened to first.

I was surprised by what I heard. In my original review of the Celebration in the February 2001 Stereophile, I described it as “an extremely well-balanced, rich-sounding, reasonably detailed transducer. Its pronounced but not excessive bass response helped create big but well-controlled sonic pictures, the midrange was on the warm yet slightly dry side, and the top was extended but certainly not up there with faster, airier, ultra-detailed…cartridges.” I continued: “the Celebration, like the EMT TU-3 Geyger I reviewed [in February 2000], sounded rich and vivid, with a slight but cannily drawn bass bump, a golden midrange glow, and a crisp, grain-free, but not hyper-extended top end.”

Mounted on the combo of SME IV.Vi plus 30/2, the Celebration sounded far more neutral, with outstanding bass control and rhythmic certainty. I heard no “bass bump” or “pronounced…bass response” or “golden midrange glow.” While I’d enjoyed the Celebration before, it now sounded much better, more neutral. Of course, the Celebration was “voiced” on the SME 30/2 with SME IV.Vi arm!

The combination of this tonearm, cartridge, and turntable produced a singularly neutral-sounding front-end. Music emerged from velvety quiet, jet-black backgrounds reminiscent of what the Rockport System III Sirius had produced. Bottom-end control and, especially, bass weight were remarkably solid and confident, with impressive pitch definition and dynamic control, and without romantic midbass overhang or warmth.

Those Sumiko boys listened well, but what I heard provoked as many questions as it answered. Was the Celebration sound I’d originally heard the actual sound of the cartridge, accurately reproduced via the Yorke-Immedia’s neutral front-end? Or was that front-end adding “character” to a neutral cartridge? If the former was true, the SME arm/’table combo imparted a lean, bass-subtractive quality to the sound, neutralizing the cartridge’s attractively rich qualities. That would play into the hands of the 30/2’s detractors, who say it sounds “antiseptic,” unable to convey the “tune” (the Linn Sondek‘s most oft-cited positive attribute). Which was it?

Some CD-Rs I’d made using the Rockport and the Boulder 2008 phono preamplifier (though not at the same time) were somewhat helpful in answering this question. Too bad I no longer had the Boulder available, but the combination of Manley Steelhead and Model 30/2 was quietly spectacular, even in comparison to nothing but real live music.

Using the SME 30/2 was a consistent pleasure. Once set up, it stayed that way, requiring no further fiddling or maintenance. I divided my listening time between the SME and the budget ‘tables surveyed in the January and February 2003 installments of “Analog Corner” (losing SME time hurt!), and the single biggest difference noted between any of those budget ‘tables and the SME was the 30/2’s pitch-black backgrounds. More than just the welcome silence, dropping the noise floor to free-fall levels had the effect of dramatically upping the dynamic range. No CD player I’ve ever heard matched the dynamic capabilities of the SME 30/2—I don’t care what the specs say.

An electrical engineer named Ronald Baumann wrote a paper someone sent me, arguing that a proper reading of analog vs digital specs confirms what vinyl enthusiasts hear: LPs do have wider dynamic range. But that’s for another discussion. For this one, thanks in part to its superbly quiet, ultra-low-tolerance bearing, the 30/2 delivered the quietest jet-black backgrounds I’ve heard yet from a turntable. Only the Rockport System III Sirius offered competition.

Antiseptic?

Perhaps if you’re used to and comfortable with such typical turntable colorations as midbass warmth induced by plinth vibrational energy, and upper-frequency sparkle caused by microvariations in speed and/or spring-suspension resonances, you might find the SME Model 30/2 “antiseptic,” as its detractors claim. What I experienced was—along with the Rockport System III Sirius—the most neutral, colorless, stable, and revealing turntable I’ve (n)ever heard. This ‘table ruthlessly revealed less-than-perfect cartridge alignment; until this was correct in every parameter, the sound could be cold, off-putting, relentless—like bad digital. But blaming the turntable for delivering the message is ridiculous. Once the setup of any of the cartridges I auditioned had been corrected, the 30/2 delivered the glories of great analog you’d expect and demand from a $25,000 turntable. Remove the turntable colorations, and the sonic differences among cartridges and arms are clarified and magnified.

Rock-Solid Bass

Bass control, definition, extension, dynamics, and harmonics were better through the SME 30/2 than through any other turntable I’ve ever heard, including the Rockport. This is the one place where the SME had a decisive edge. Image solidity and textural clarity in the bottom octaves were unsurpassed by a wide margin in my experience—which includes the Boulder-Yorke combo, and the Yorke is damn good on the bottom. You have to experience a familiar, well-recorded timpani thwack through the SME to understand what I’m talking about.

Spectacular Attack!

Most obvious among the SME Model 30/2’s many strong suits were its transient speed and attack. Like the Rockport, the 30/2’s rendering of the piano on even mediocre recordings was in another league compared to every other ‘table I’ve heard (though my reference Simon Yorke is very good in this regard). Attack and control of the piano’s lowest notes was rock-solid, creating a strong rhythmic foundation for the notes in the middle and at the top of the keyboard. Post-attack, the 30/2 delivered the piano’s harmonics with greater clarity, solidity, and seamless integration than any other ‘table I’ve heard—and that includes via the Rockport.

The 30/2 delivered individual piano notes with a physical palpability that made each an event worth noting—something often heard in concert, but rarely on records. What the Boulder 2008 had managed electronically the SME accomplished mechanically. What the two together would deliver, and whether it would be positive, I can’t say. Analogue Productions’ 45rpm edition of Bill Evans’ Waltz for Debby (AJAZ 9399) delivers the piano cleanly, minus the usual boxiness and fog. Via the SME, this recording had a physical solidity and harmonic richness I didn’t think could possibly be on the tape. The set had arrived after the SME, so I needed to go back to the 33 1/3 edition to determine how much of what I was hearing was the record, how much the turntable. The 33 1/3 version, while not as good, was far more impressive than I remember it being, so accomplished was the SME’s speed stability and lack of coloration.

Glorious Decay, No Zippy Edge

With its exceptional speed stability, apparent lack of mechanical resonances, quiet bearing, and superb isolation, it was no surprise that the SME 30/2 produced exceptionally solid, stable images—but those qualities also helped the ‘table to deliver believable decay and noticeably low harmonic coloration. Like a low-resonance, flat-response loudspeaker, on first listen the SME 30/2 could sound soft and muted on top, and lacking in detail resolution (but if the cartridge was poorly set up, it could sound bright, hard, and unpleasant). Once I’d adjusted to the 30/2’s apparent lack of high-frequency resonances, I realized I was hearing more harmonic and event details, and fewer of the edgy peaks that induce false details.

Losing the peaks radically improved the harmonic believability of instruments while accentuating differences in the high-frequency performance of cartridges. The high-frequency response characteristics of such top-of-the-line cartridges as Koetsus, Dynavectors, van den Huls, Benzes, Transfigurations, Clearaudios, Lyras, Grados, and others vary greatly. With the SME, even subtle tonal differences among cartridges registered; as with the Sumiko Celebration, I found myself surprised by the sounds of even more familiar cartridges.

Lyra’s Helikon and Titan cartridges sound extremely neutral to me, though those who like the lusher sound of some Benzes and Dynavectors find them drab and colorless. But instead of sounding even more colorless through the less colored SME, the Helikon and Titan actually sounded richer, more fleshed-out and coherent, than I was used to hearing them through the Simon Yorke. How can that be? I figure the Lyras’ extended high-frequency energy (compared with the more muted-sounding cartridges) excited resonances in the Yorke but not in the SME, hence the latter’s smoother sound.

One night I went through almost the entire The Complete Studio Recordings of the Miles Davis Quintet: 1965-1968 (Mosaic MQ10-177, 10 LPs), marveling at the precise image of Miles standing before the microphone, and the wealth of musical and thought detail I’d simply never heard before. I pulled out what I’d thought was an undistinguished-sounding disc, an original RCA Ziggy Stardust (UK, SF 8287), and found that it was amazingly distinguished. And I discovered that when mastering engineers play serious games with EQ, the “ledges” stick out obtrusively, as on too many original Mobile Fidelity Sound Lab LPs.

The problem with telling such hyperventilating stories only a few months after my July 2002 review of the Boulder 2008 is that it sounds like the same old song. The fact is, the SME 30/2, like the Boulder, actually is that good—and better. It allowed every record I threw at it to sound more detailed, yet less edgy and artificial. Its sense of rhythmic certainty and its ability to unravel and clarify complex musical passages never failed to amaze. Was it better than the Rockport? In the bass, yes. I’m confident of that, despite the changes in my system since that review. Otherwise, I’d say the SME and the Rockport are at least on a level playing field, with tradeoffs on both sides.

I found no negatives. While I’d found the SME 10 to sound somewhat dry, with perhaps a “skeletal” harmonic quality from the midbass to the upper midrange, the Model 30/2 exhibited no such coloration. The SME 30/2 is perhaps the most tonally neutral turntable I’ve ever heard. Only the Rockport System III Sirius, which includes an integral tonearm, is in the same league, and it doesn’t stand up to the SME’s low-frequency extension and solidity.

Choice of Arms?

My review sample of the SME Model 30/2 came with the SME IV.Vi tonearm, which I covered in the SME 10 review in the April 2000 issue, so I won’t repeat myself here. But I did get hold of a Graham armboard so I could try two arms. Rick Rosen was visiting when I decided to make the switch. We listened to the SME IV.Vi for a while, then auditioned the Graham 2.2. One of the records we played was a test pressing of the vinyl edition of Alison Krauss’s Forget About It (Diverse DIV 002LP), cut from a DSD master. We compared that to the SACD (Rounder 11661-0465-6) on the recently arrived combo of dCS’s Elgar Plus DAC, Purcell upsampler, and Verdi SACD transport (currently under review).

Interestingly, the Graham 2.2 (with Lyra Titan cartridge) more closely resembled the SACD than did the SME IV.Vi. Both the SACD and the vinyl through the pairing of Graham 2.2 and SME 30/2 revealed a pleasant, warm cushion behind Krauss’s voice. The SME IV.Vi dried that out a bit, giving the overall sound the precise “skeletal” harmonic quality, from midbass to upper midrange, that I’d complained of in the SME 10 review.

In any case, while both arms sounded great on the SME 30/2, Rick and I agreed that, if we were buying an SME 30/2 for my system, we’d go for the Graham 2.2. Detractors of unipivot arms would say that the Graham’s inability to control bass energy was adding the warmth we heard and preferred, but we heard it on the SACD too. That was good enough for us.

Conclusions

A tour of the SME factory a few years ago and a visit with designer Alastair Robertson-Aikman convinced me that few, if any, companies in high-end audio can match SME’s machining prowess. The company does precision CNC machining and measuring for the medical industry, for Formula One racing, for aerospace and aviation, and, fortunately for audiophiles, for the audio industry.

The SME Model 30/2’s precision-machined parts (including an ultra-quiet, ultra-smooth-running main bearing), its superb damping and isolation, its high-mass, low-flex plinth, its accurate, stable drive system, and, most of all, its sound or lack thereof, might just make it the finest turntable in the world. It’s certainly one of the two best I’ve (n)ever heard, and the other one costs more than twice as much (but includes an integral arm).